|

| August 10, 2021 | Volume 17 Issue 30 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

Why hybrid bearings are becoming the new industry standard

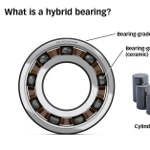

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

3M and Ansys train engineers on simulating adhesives

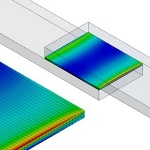

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

What can you secure with a retaining ring? 20 examples

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

See the Smalley design applications.

Load fasteners with integrated RFID

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

Learn more.

Couplings solve misalignments more precisely with targeted center designs

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

Learn more.

What is 3D-MID? Molded parts with integrated electronics from HARTING

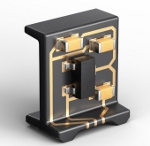

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Scientists discover why we can find gold at all -- and why finding it can be deadly

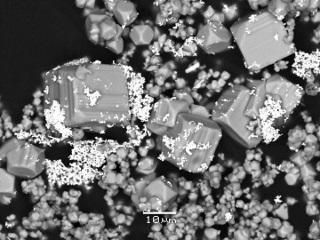

Scanning electron microscopy photomicrograph showing gold microparticles (bright color) deposited with pyrite crystals from a hydrothermal solution in a laboratory experiment. Such experiments simulate the formation of gold deposits in nature. [Credit: Maria Kokh and Gleb Pokrovski]

Why are gold deposits found at all? Gold is famously unreactive, and there seems to be little reason why gold should be concentrated, rather than uniformly scattered throughout the Earth's crust. Now an international group of geochemists has discovered why gold is concentrated alongside arsenic, explaining the formation of most gold deposits. This may also explain why many gold miners and others have been at risk from arsenic poisoning. This work was presented at the Goldschmidt conference, after recent publication.

Gold has been prized for millennia, for its purity and stability. It's also rare enough to retain its value -- the World Gold Council estimates that all the gold ever mined in the world would fit into a 20 x 20 x 20-m cube. It is valued for its beauty, but also because it is one of the most inert metals in the whole Periodic Table; it doesn't easily react with other substances. So why should gold come together in sufficient quantity to mine -- why are there gold deposits at all?

Some gold is found as gold nuggets, the stuff of prospectors' dreams, but an appreciable amount is bound up with minerals. Gold is known to be related to iron- and arsenic-containing minerals, such as pyrite and arsenopyrite. These minerals act sort of like a sponge, and are capable of concentrating gold up to a million times more than is found elsewhere in nature, such as in the hot spring waters that transport the gold. This gold becomes chemically bound in these minerals, so it is invisible to the naked eye.

The scientific team studied the action of the gold-concentrating minerals using the intense X-ray beam produced by the European Synchrotron (ESRF) at Grenoble in France, which can probe the chemical bonds between the mineral and gold.

They found that when the mineral is enriched with arsenic, gold can enter the mineral structural sites by directly binding to arsenic (forming, chemically speaking, Au(2+) and As(1-) bonds), which allows gold to be stabilized in the mineral. However, when the arsenic concentration is low, gold doesn't enter the mineral structure but only forms weak gold-sulfur bonds with the mineral surface.

Lead researcher Dr. Gleb Pokrovski, Directeur de Recherche at CNRS, GET-CNRS-University of Toulouse Paul Sabatier (France), said, "Our results show that arsenic drives the concentration of gold. This arsenic-driven gold pump explains how these iron sulfides can massively capture and then release gold, so controlling ore deposit formation and distribution. In practical terms, it means that it will make it easier to find new sources of gold and other precious metals, which bind to arsenic-containing iron sulfides. It may also open the door to controlling the chemical reactions, and if we can improve gold processing, we can recover more gold."

The new model identifies just why gold tends to be found with arsenic.

Dr. Pokrovski continued, "It has been known for centuries that gold is found with arsenic, and this has caused severe health problems for gold miners. Now we know what happens at an atomic level, and we can begin to see if there's anything we can do to prevent this."

The noxious link between arsenic and gold is well known in France and elsewhere in the world, including at the Salsigne mine near Carcassonne. This was one of Western Europe's largest gold mines, and the world's largest arsenic producer at one time. It closed in 2004, but the environmental consequences of the arsenic pollution still persist in the region.

Dr. Jeffrey Hedenquist, University of Ottawa (who was not involved in this work), commented, "Geologists as well as prospectors have long known that gold can be associated with arsenic-rich minerals, and over the past few decades others have quantified this association. The findings of Dr. Pokrovski and his team now help to explain why we see this association, caused by an atomic-scale attraction between gold and arsenic, with this marriage arranged by the structure of certain minerals."

Source: Goldschmidt Geochemistry Conference

Published August 2021

Rate this article

View our terms of use and privacy policy